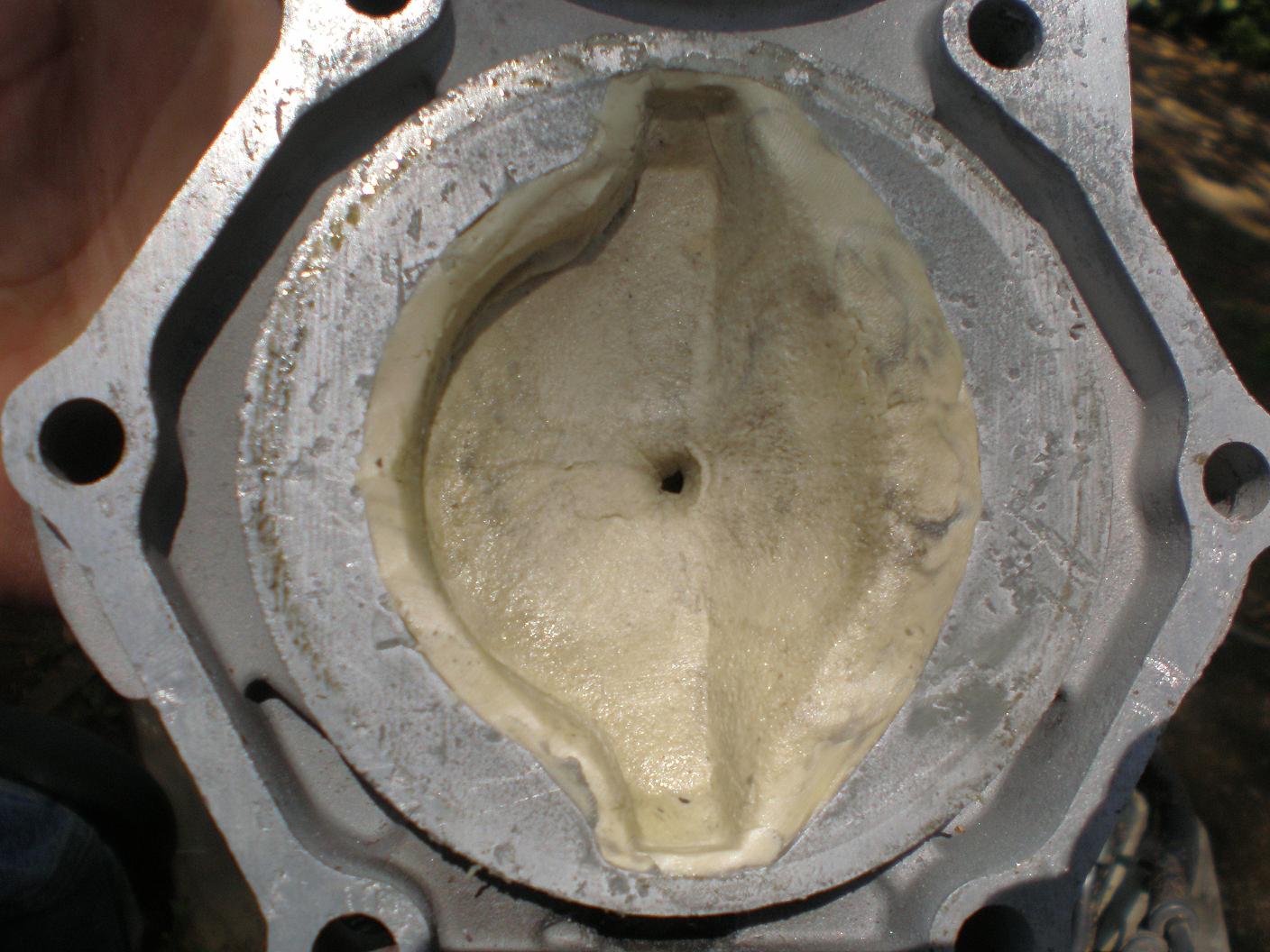

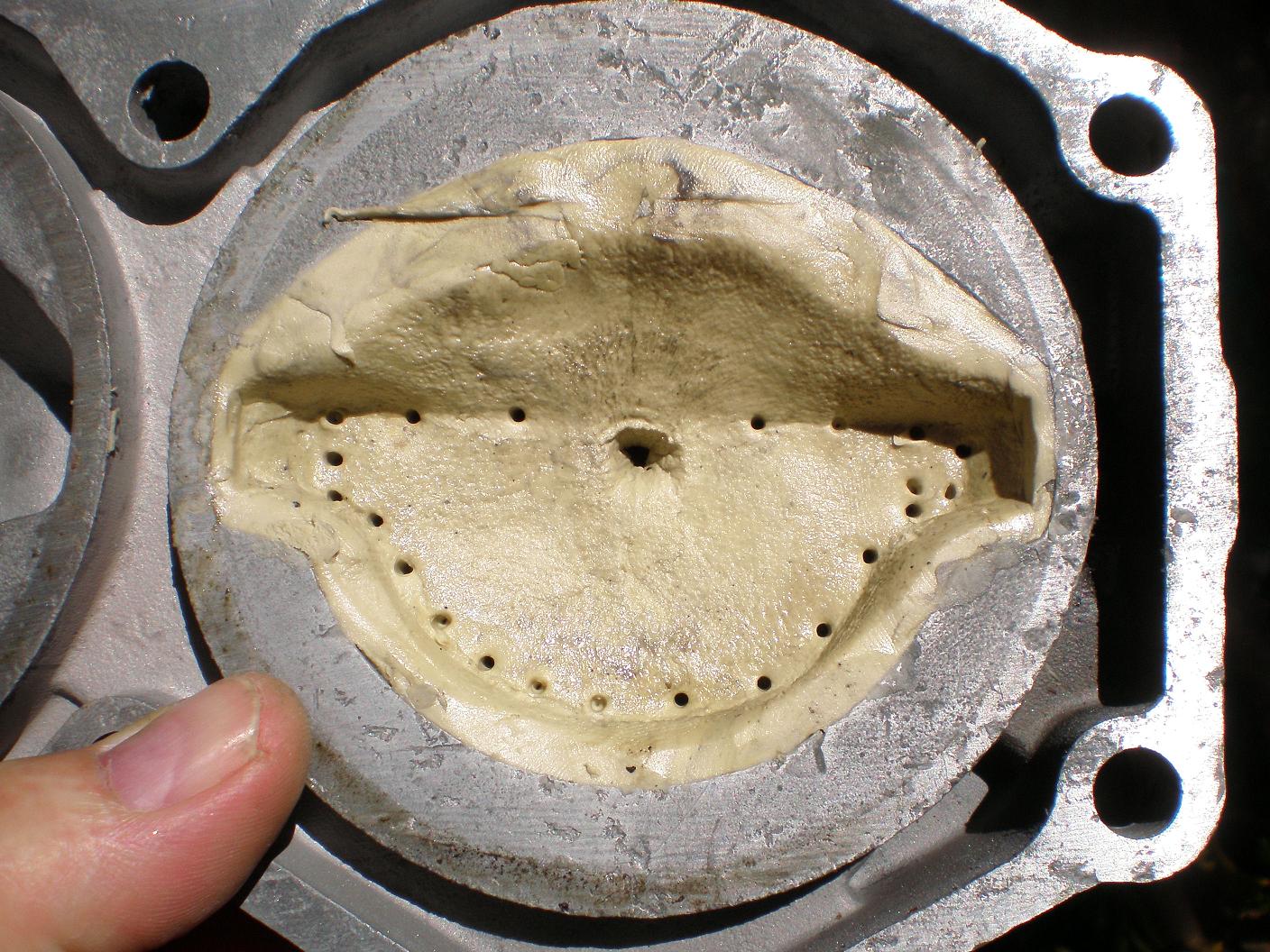

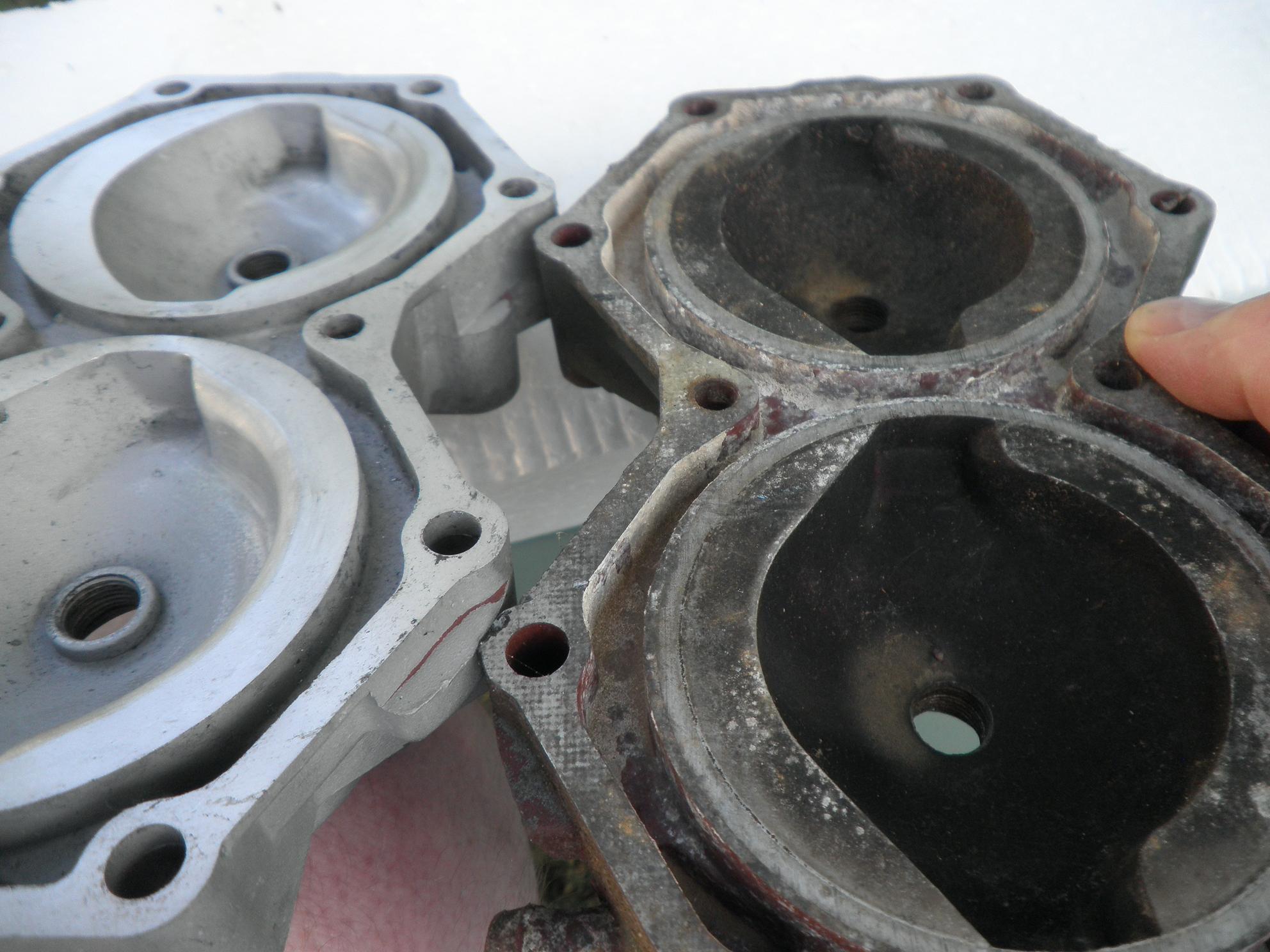

People often ask about raising compression to improve performance of an old engine. It can be done - but care must be taken to do the job correctly. Also, this is not advisable for all engines. The best candidates for this type of mod are the old OMC V4 engines up the the 1968 models. The early engines had low compression, and some can be improved by this mod. As a disclaimer - you must understand that you assume a degree of risk when doing modifications to your engine. Engines that push very heavy loads should not be modified. but done carefully and correctly, this is normally a very safe modification to these engines. For starters, if you want more compression, you have to see if doing the mod is possible. You need to know the "squish" clearance between the piston and the combustion chamber ceiling first. Here is how to do it. Get a tub of plumber's putty, or modeling clay. Remove the head & pack one combustion chamber with putty. Re install the head with the gasket. Rotate the engine one full revolution SLOWLY by hand. This will smash the putty and show how much of a gap there is between the piston and the combustion chamber ceiling. The excess putty will be pushed out of the spark plug hole. Carefully remove the head and lay it on a flat surface or table. Lay a straight edge across the open side of the head. Take a welding rod or similar stiff wire & make it into a measuring tool. use a hacksaw to etch a horizontal line on the rod every 1/32" or 1/16" inch from the end of the rod. You will only need to do about 1/2" of lines up the rod. Now take the measuring rod and probe the depth of the putty. Be very careful when doing this. Probe along the outline of the piston deflector eyebrow - as this is where clearance is usually the tightest. Record the depth of EACH hole. It is best to use a dial caliper to do this - a measuring tape or ruler is not nearly enough accurate. You can plunge the rod into the putty till it hits bottom. Now look at the results - the smallest distance is the distance from the piston to the head. You can safely cut material off the head as long as there is no less than 0.125" between the head and piston at the TIGHTEST spot. Example: Probed head clearance shows 0.250" at TIGHTEST location. OK to mill up to 0.125" from head. This will leave 0.125" clearance with gasket installed. Have the heads milled by an experienced and skilled machinist. When the heads are done, Check the clearance to be sure the correct thickness of material was removed. Install them with New gaskets following the manufacturer's torque specs and procedures for the engine. Rotate the crankshaft by hand to see that there is no binding or clunking. Be sure that the pistons adequately clear the heads before starting the engine. Do not take shortcuts. Do not exceed OEM torque values.

You may also consider using a cooler plug if you plan to run the engine hard. We can talk about plug heat ranges in another article.