As always Doc has gone above and beyond taking the time with verbiage and pictures.

I will try to add...

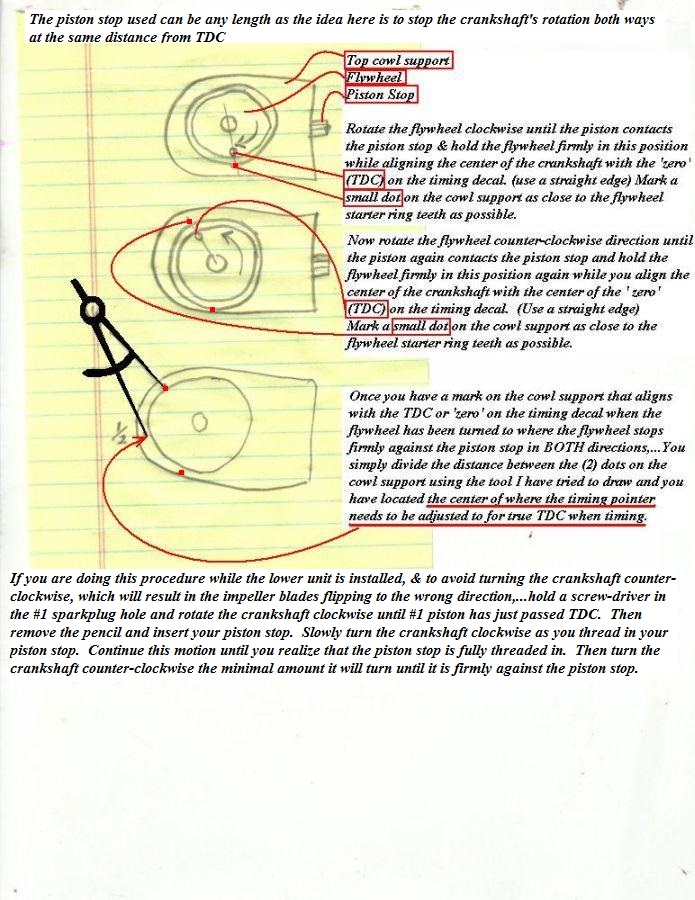

I have found most people get confused over the first part of the procedure finding top dead center with the fake plug to set pointer. This is something that is NOT done on most gas motors you would encounter. The good Carl Kiekahfer and company were perfectionist and wanted to make sure TDC on the timing label, when lined up with the pointer was indeed the top most location of piston travel, or actual TDC. So they made the pointer adjustable, so when true piston TDC is found you adjust the pointer location to align with the TDC on the label.

Some earlier year inlines ( non direct charge)with thunderbolt ignition had no adjustments, you just timed using the label markings and line on the flywheel. The very early inlines with points had no timing marks and everything was done based on the piston location, they have a special dial indicator for this. Anyways, the obsession for absolute accuracy does make it cumbersome to set up or at least recheck. Keep in mind once you have done this, you won't need to do it again....unless the hold down bolt loosens!

I have surmised that the inlines with direct charge where found to be very fussy on ignition timing so a better level of accuracy was needed than on the cross flow types. One sees a dramatic reduction in full spark advance on the direct charge motors Approx 21 degrees full on a direct vs 34 to 36 or so on cross flow inlines and Merc revised total timing downwards on the 1500's to minimize detonation by only 2 degrees so small changes mattered to them...I digress, but this should be checked.

Back to no spark,

One thing that comes to mind is the ignition switch is not on, so switchbox is not powered, key should be turned to "run" position. You could also run a jumper from the red wire to the white terminal on the 4 terminal side of the switchbox. The red is always hot and the white is the switched hot.

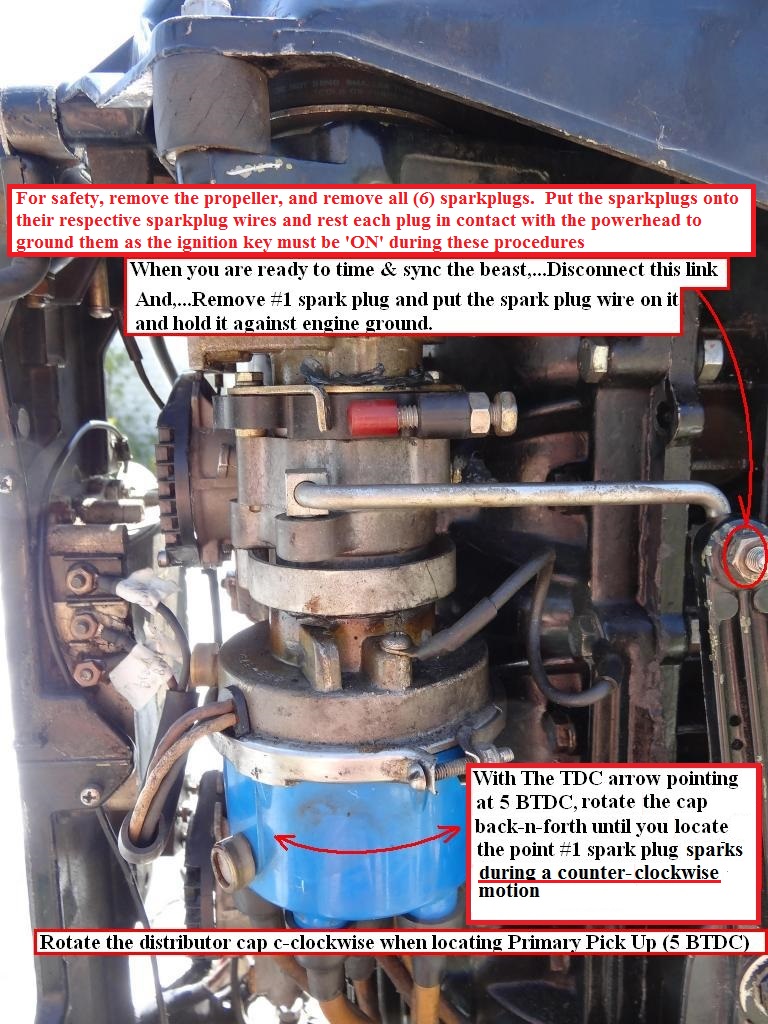

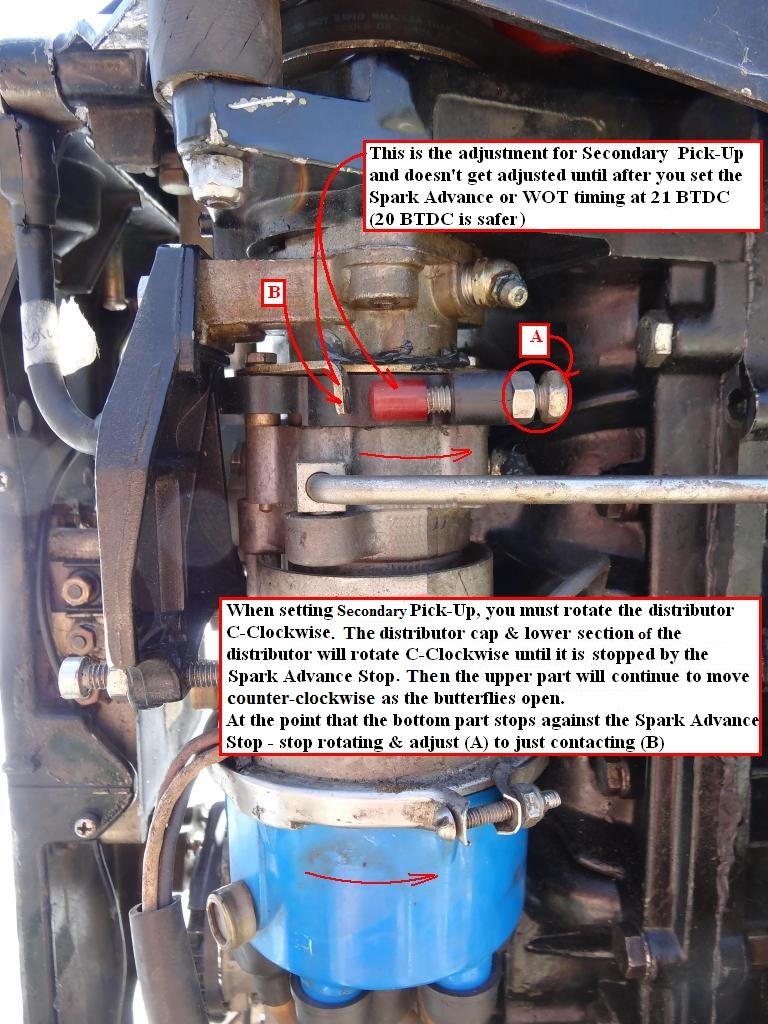

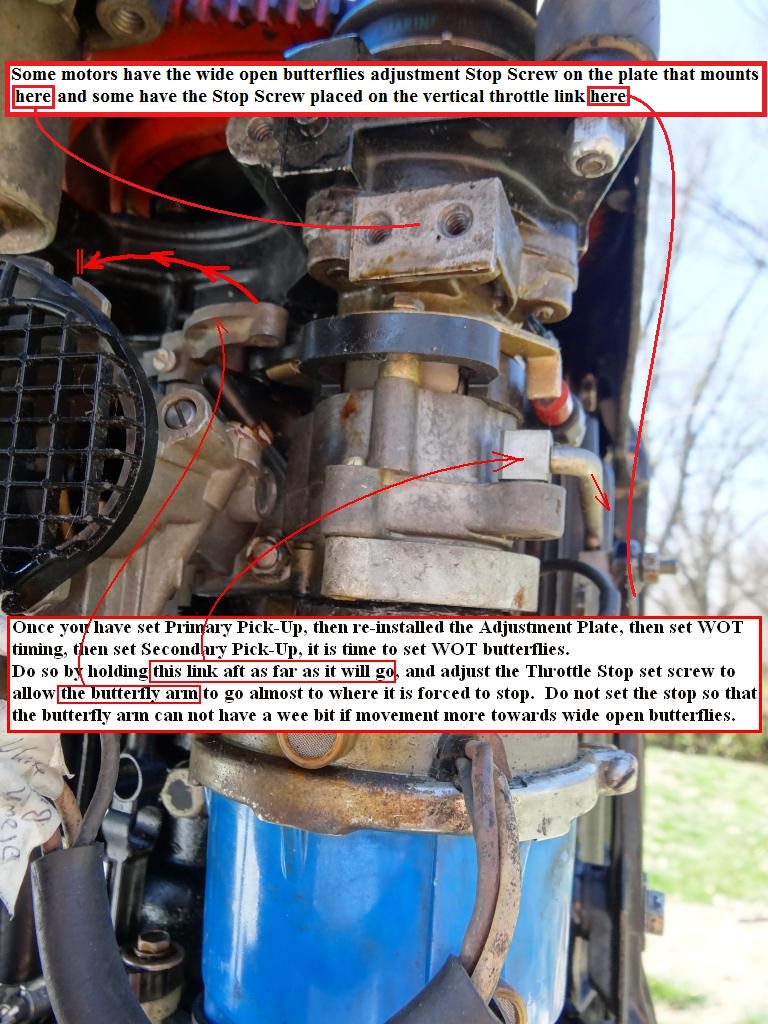

You may not be rotating distributor clockwise far enough so when you rotate it CC it will "trigger". The trigger wheel in the distributor is a series of rectangular holes and the metal between holes must pass through the pick-up in the distributor to trigger the switchbox. These are inductive type triggers so it senses when metal cuts across the small electrical field in the pick-up ,it is not like an LED system that triggers when it sees the light signal through the window. It is the action of the metal passing through you are doing to induce the system to fire so make sure that is what is happening. It is the movement of the metal portion past the pick-up that will trigger the switchbox.

This is exactly analogous to a points system based firing exactly as points open ( if you are old enough to know those!!)

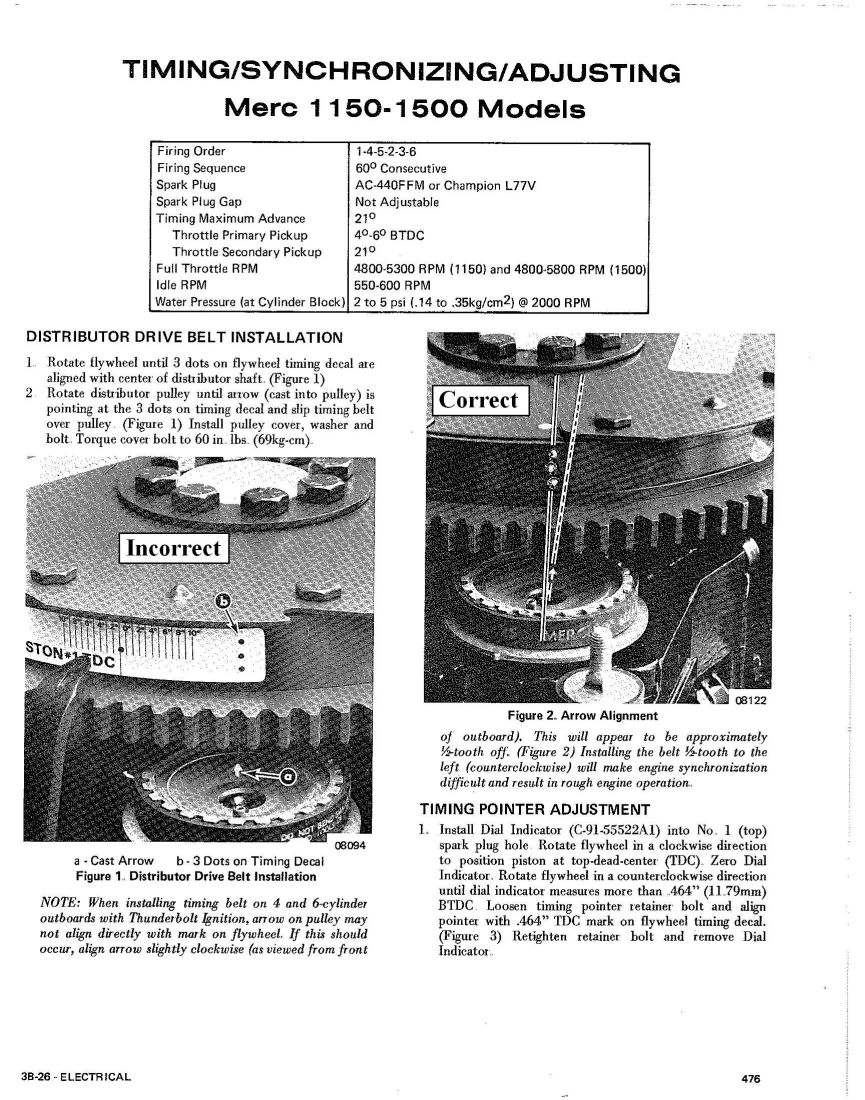

Another gottcha is if you or someone replaced timing belt and got it wrong, recheck this simply by removing the distributor pulley top cover and check arrow and flywheel alignment, it is easy to get this wrong by one cog unless you have done it a few times.

Well good luck it all seems a bit involved the first time doing this so I hope it's helpful to understand what each step is for rather than simply following instructions.

Randy