Pretty sweet looking 800DR. Is it a long shaft or short??

IMHO,...

Pre-lube the cylinder walls with a 25:1 fuel mix via the spark plug holes. Then slowly rotate the flywheel for a few minutes to allow the lube to dissipate. Then do compression tests.

If the compressions check out good,...

You really should lift the powerhead and pull the bottom end cap.

It is pretty common (in my area anyway) that ambient moisture has trickled down over the years and compromised the bottom main bearing.

You can remove the bottom end cap without splitting the crankcase open. Use a common puller, and ease it out.

Don't try to pry it out - you will damage the shims and risk ruining the end cap and/or block surface.

Once the end cap is removed, You will be able to inspect the ball bearing for rust & pitting, etc.

Then heat the end cap with a MAPP gas torch, and the bearing will fall out at about 200*.

Inspect the bearing again, and while it is out, replace the (2) seals and replace the o-ring.

To reinstall the end cap, start with extra long 5/15 NC cap-screws to guide the end cap is straight. Grease the o-ring and O.D. of the end cap. Gently tap the end cap periodically with a soft blow hammer as it goes into the block.

I would also strongly encourage you to pull the flywheel and R&R the top end cap.

When you do,...Be sure and mark the distributor pulley & flywheel using the specific timing marks, before you pull the flywheel.

Just post if you need any insight in any of this stuff.

All the seals, bearings, and o-rings are available.

Once these maintenance updates have been completed, everything else should be external, but if it has been used in salt water, you really should disassemble the port side cover and carefully inspect the baffle plate for corrosion caused breaks down in the deep valleys of the casting.

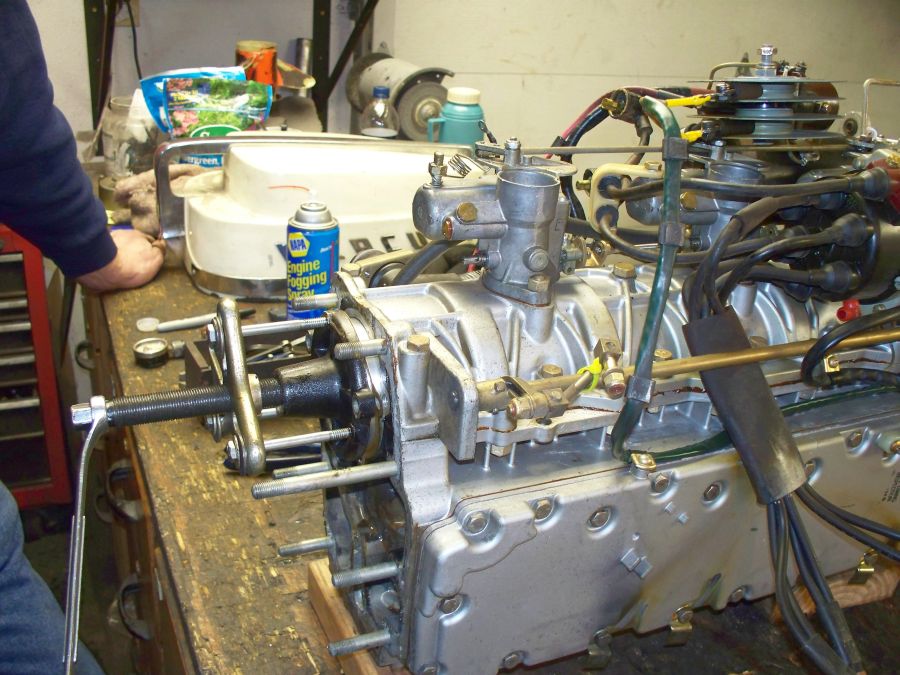

The attached pictures are of a very well kept, salt free Merc 1000, from eastern Washington state, but still, time takes its toll.

doc